Product Description

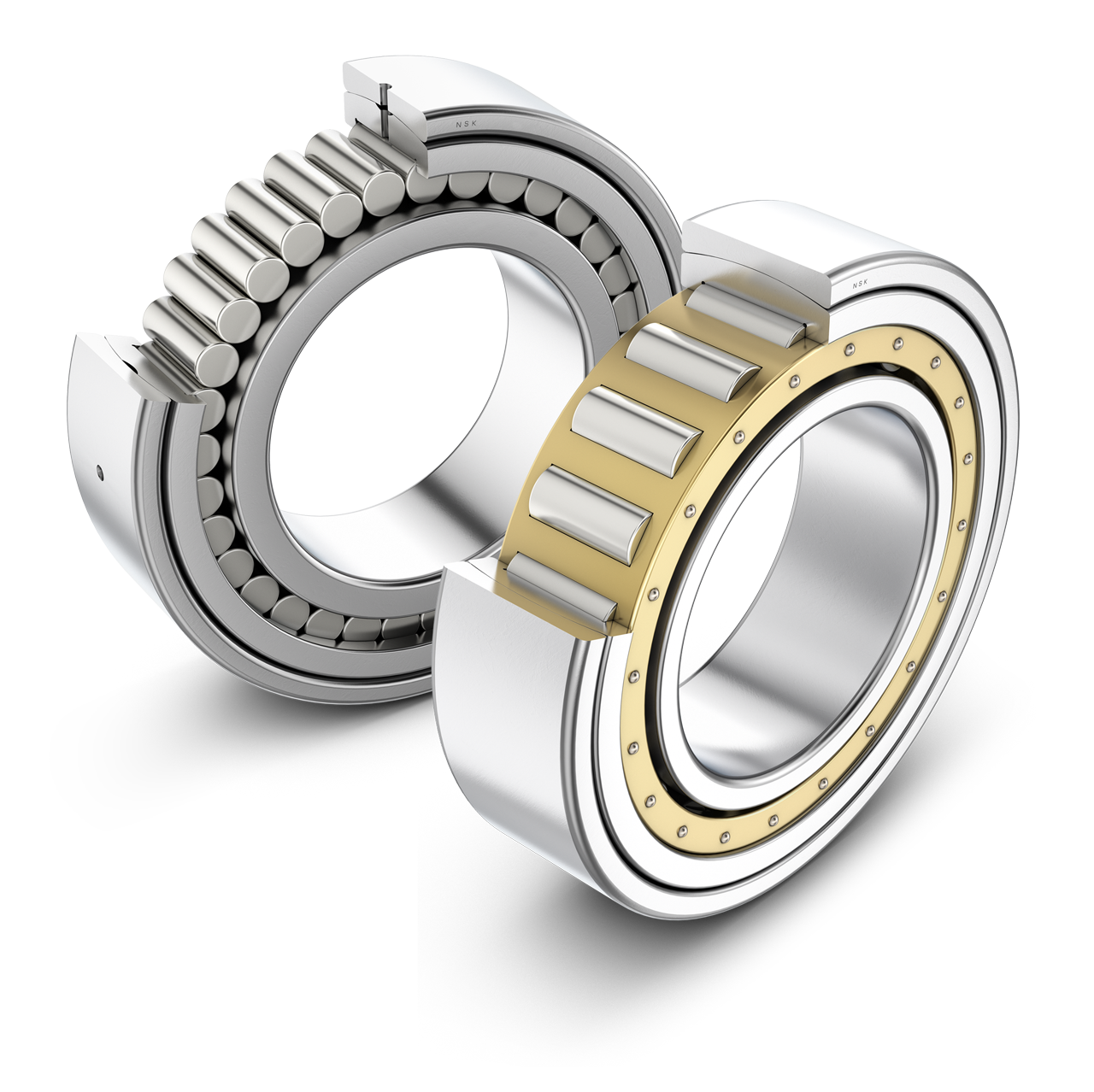

Premium Quality NJ221EM Cylindrical Roller Bearing 105*190*36mm China Manufacturer

Bearing Specification :

| Model Number | NJ 221 ECP |

| Bearing Name | Cylindrical Roller Bearing |

| Brand | FSK / KBE / SKB / OEM |

| Material | Gcr15 Chrome Steel |

| Number of Row | Single Row |

| Dimensions(mm)(d*D*b) | 105*190*36mm |

| Weight / Mass ( KG ) | 4kg |

| HS Code | 8482800000 |

| Original Country Show | CHINA |

Bearings Detailed Picture:

Other Bearings We Offer:

| Hot Sales in our company |

| 1. deep groove ball bearing 6000,6200,6300,6400,61800,61900,Z,RS,ZZ,2RS |

| 2. spherical roller bearing 22200,22300,23000,24000,23100,24100,CA,CC,E,W33 |

| 3. cylindrical roller bearingN,NU,NJ,NN,NUP,E,ECP,ECM,ECJ |

| 4. taper roller bearing 35710,30300,32200,32300,31300,32000 |

| 5. Aligning ball bearing 1200,1300,2200,2300, |

| 6. needle roller bearing NA,NAV,NK,NKI,RNA,NK,RNAV,ZKLF,ZKLN,ZARF,ZARN |

| 7. thrust ball bearing 51100,51200,51300,51400,E,M |

| 8. angular contact ball bearing7000,7100,7200,7300,AC,BECBM,C |

| 9. spherical plain bearing GE,GEG,GEEW,U,UC,UG,GX,GAC,SA,SABP |

Our Advantage:

About FSK Factory Condition :

FAQ:

1.How can I get the bearing price?

Mike: You can leave your message on Alibaba, or conact us directly by email, , SkYPE, Viber. Tell us your quantity, usually 2-5 hours you will get the price.

2.How can I buy them?

Mike: You can place order on Alibaba, or pay the payment by Western Union, Paypal, T/T and L/C.

3. How long I can get these bearings?

Mike: for small order, we will delivery the bearings in 1-2 days after recive your payment. usually 3-5 days will arrive in your place by international express, such as DHL, TNT, UPS and so on. For big order, please contact us.

4.How to protect the bearing quality?

Mike: All procudts passed ISO9001:2008 and ISO14000 certificates. we can accept small sample order, you can check the quality.

5. Other service.

Mike: We can offer OEM service according to your demand.

FSK Bearing Company Advantages:

(1) We have first-class testing equipment to detect bearing various data parameters and control the quality of the bearing.

Whenever bearings must first detected whether the quality is qualified and the unqualified bearing will be eliminated directly.

So we can get the trust of a large number of customers, and supply them for several years.

(2) We have our own R & D capabilities, to help customers solve the problem of non-standard bearings.

We can also according to customer requirements change their own mark.

(3) Price, our manufacture ensure that our prices across China are quite competitive.

It is better for you to compare prices and quality among suppliers.

But everyone knows you can not buy the highest quality products with the lowest price,

but our product is the best quality if you use equal price.

FSK Cooperation Details

Delivery:

For Small weight or ungent ,we send by express UPS,DHL,FEDEX, or EMS,china post with Thracking number

For max production , we will ship by sea/air.

Payment Item:

TT, 30% deposit , 70% before shippment.

L/C At Sight

Paypal Or Western Union In advance

Service:

Trade Assurance

Payment Protection

Timely Delivery Guaranteed

Product Qualtity Protection

Premium Quality NJ221EM Cylindrical Roller Bearing 105*190*36mm China Manufacturer , Get Cheap Price from China Bearing Factory Now !

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Medium and Large(120-190mm) |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the Steps for Proper Installation and Alignment of Tapered Roller Bearings?

Proper installation and alignment of tapered roller bearings are essential to ensure optimal performance, reliability, and longevity. Incorrect installation can lead to premature wear, reduced efficiency, and even catastrophic failure. Here are the steps to follow for the correct installation and alignment of tapered roller bearings:

- 1. Clean and Prepare the Components:

Thoroughly clean the bearing components, including the bearing housing, shaft, and associated parts. Remove any dirt, debris, or old lubricant that could impact the bearing’s operation.

- 2. Choose the Correct Tools:

Use appropriate tools and equipment for the installation, such as bearing heaters for controlled heating and proper fit. Avoid using excessive force or striking the bearing directly, as this can damage the components.

- 3. Inspect the Bearings:

Before installation, visually inspect the tapered roller bearings for any signs of damage or defects. Ensure that the rollers and raceways are clean and free from contaminants.

- 4. Apply Lubrication:

Apply the recommended lubricant to the rollers, raceways, and other bearing components. Proper lubrication is crucial for reducing friction, dissipating heat, and preventing premature wear.

- 5. Mount the Bearings:

Mount the bearings onto the shaft or into the housing using appropriate methods. Avoid applying excessive force directly to the bearing components, as this can lead to damage. Utilize specialized tools like bearing pullers and press tools if necessary.

- 6. Ensure Proper Alignment:

Proper alignment is critical to prevent excessive loads, misalignment, and premature wear. Use precision measurement tools to ensure the bearing is aligned with the shaft and housing within specified tolerances.

- 7. Apply Controlled Heat:

If necessary, apply controlled heat to the bearing components to aid in expansion and facilitate proper fit. Ensure that the heat is applied uniformly to avoid distortion or damage.

- 8. Use Adequate Preload:

If specified for your application, apply the appropriate axial preload to eliminate internal clearance and optimize load distribution among the rollers.

- 9. Secure Bearings:

Secure the bearings in place using locking mechanisms, such as locknuts, to prevent unintended movement and ensure proper retention.

- 10. Verify Fit and Function:

After installation, verify that the bearings are properly seated, aligned, and functioning as intended. Rotate the shaft to ensure smooth operation and absence of unusual noise or vibration.

- 11. Document the Installation:

Keep a record of the installation process, including alignment measurements, preload values, and any relevant notes. This documentation can aid in future maintenance and troubleshooting.

Proper installation and alignment are essential to achieving optimal performance and longevity from tapered roller bearings. Following these steps ensures that the bearings operate smoothly and reliably within their intended applications.

What are the potential challenges or limitations of using cylindrical roller bearings in specific industries?

While cylindrical roller bearings offer numerous advantages, there are also certain challenges and limitations associated with their use in specific industries. Let’s explore some of these potential challenges:

- High-Speed Applications:

In industries that require high-speed rotating machinery, such as machine tools or centrifugal compressors, the limitations of cylindrical roller bearings become more pronounced. At high speeds, factors like centrifugal forces, increased operating temperatures, and the potential for roller skidding can impact the bearing’s performance. Special design considerations, such as optimized cage designs, precision manufacturing, and proper lubrication, are necessary to overcome these challenges and ensure reliable operation at high speeds.

- High-Temperature Environments:

In industries like steel production, glass manufacturing, or certain types of furnaces, the operating temperatures can exceed the limits of standard cylindrical roller bearings. High temperatures can cause dimensional changes, affect the lubricant properties, and lead to accelerated wear or premature failure of the bearing components. To address this limitation, specialized high-temperature bearings with heat-resistant materials, advanced lubrication systems, and appropriate sealing mechanisms are required.

- Heavy Load and Shock Loads:

Industries involving heavy machinery, such as construction, mining, or material handling, often subject cylindrical roller bearings to extremely heavy loads or sudden shock loads. These conditions can lead to increased stress, fatigue, or even permanent deformation of the bearing components. To overcome these challenges, bearings with higher load-carrying capacities, robust designs, and enhanced fatigue resistance are necessary. Additionally, proper maintenance practices and regular monitoring are crucial to detect any signs of excessive load or potential failure.

- Contamination and Harsh Environments:

In industries characterized by harsh operating environments, such as agriculture, forestry, or automotive manufacturing, cylindrical roller bearings can face challenges related to contamination, moisture, or exposure to abrasive particles. Contaminants can accelerate wear, cause damage to the bearing surfaces, or impair the lubrication effectiveness. Sealing solutions, effective maintenance practices, and the selection of appropriate bearing materials are essential to mitigate these challenges and ensure reliable performance in such environments.

- Space Limitations:

In certain industries like aerospace or robotics, where space is limited and compact designs are required, the size and dimensions of cylindrical roller bearings can pose challenges. Finding suitable bearing sizes that meet the specific space constraints while still fulfilling the load and performance requirements can be a limitation. In such cases, alternative bearing types or customized bearing solutions may be explored to overcome the space limitations.

It’s important to note that while there may be challenges or limitations associated with using cylindrical roller bearings in specific industries, advancements in bearing technology, materials, and design continue to address and overcome many of these limitations. Consulting with bearing manufacturers, considering application-specific requirements, and implementing appropriate maintenance practices can help mitigate these challenges and ensure the successful use of cylindrical roller bearings in a wide range of industries.

What are cylindrical roller bearings, and how are they used in machinery?

Cylindrical roller bearings are a type of rolling element bearing that consists of cylindrical rollers held in place by a cage. They are designed to provide high radial load-carrying capacity and moderate thrust load-carrying capacity. Cylindrical roller bearings have a relatively high stiffness and can accommodate axial displacement between the inner and outer rings.

These bearings are commonly used in various machinery applications due to their specific characteristics and advantages:

- Radial Load Capacity:

Cylindrical roller bearings can withstand high radial loads, making them suitable for applications where the primary load is radial in nature. The cylindrical rollers distribute the load evenly along their length, reducing stress concentrations and improving load-carrying capacity. This characteristic allows cylindrical roller bearings to support heavy machinery components and handle substantial radial forces.

- Thrust Load Capacity:

While primarily designed for radial loads, cylindrical roller bearings can also accommodate moderate axial loads. The arrangement of the cylindrical rollers and their contact angle with the raceways enables these bearings to handle limited thrust loads. However, for applications with predominantly axial loads, other types of bearings, such as thrust bearings, may be more suitable.

- Design Variations:

Cylindrical roller bearings come in various design variations to meet specific application requirements. These variations include different cage designs, such as solid cages or cages made of polymer materials, which offer benefits such as reduced friction and improved lubrication. Additionally, cylindrical roller bearings can have different configurations of the inner and outer ring flanges, such as separable or integral designs, to facilitate installation and maintenance.

- High-Speed Capability:

Cylindrical roller bearings can operate at high speeds, depending on their design and internal clearance. Factors such as cage material, roller design, and lubrication play a role in determining the maximum allowable speed. Manufacturers provide speed ratings and guidelines to ensure proper selection and operation of cylindrical roller bearings within their speed limits.

- Application Versatility:

Cylindrical roller bearings find wide applications in various machinery and equipment. They are commonly used in rotating machinery, such as electric motors, gearboxes, pumps, and compressors. Cylindrical roller bearings are also utilized in industries such as automotive, aerospace, construction, and mining, where they support heavy loads and provide rotational motion in critical components.

- Alignment and Compensation:

Cylindrical roller bearings have the ability to accommodate slight misalignments between the inner and outer rings. This feature allows for easier installation and helps compensate for mounting errors or shaft deflections during operation. The axial displacement capability of cylindrical roller bearings can also assist in thermal expansion or contraction of the shaft and housing.

In summary, cylindrical roller bearings are a type of rolling element bearing that provides high radial load-carrying capacity and moderate thrust load-carrying capacity. They are used in machinery applications where heavy radial loads need to be supported. With their versatility, high-speed capability, and ability to accommodate misalignment, cylindrical roller bearings contribute to the efficient and reliable operation of various types of machinery.

editor by CX 2024-04-26