Product Description

Product Description

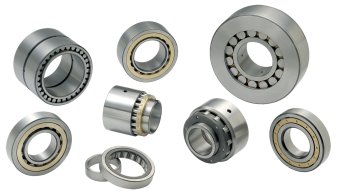

Cylindrical roller bearings with inner or outer rings without fenders, whose inner and outer rings can move relative to each other in axial direction, can be used as free-end bearings. Cylindrical roller bearings with double rim on 1 side of the inner and outer rings and a single rim on the other side of the ring can withstand a certain degree of axial load in 1 direction. Generally used steel plate stamping cage, or copper alloy car solid cage. But some use nylon forming cages.

Cylindrical roller and raceway for line contact bearings. Large load capacity, mainly bearing radial load. The friction between the rolling body and the rim of the ring is small, suitable for high-speed rotation. According to whether the ring has a rim or not, it can be divided into NU, NJ, NUP, N, NF and other single-row cylindrical roller bearings, and NNU, NN and other double-row cylindrical roller bearings. The bearing is a detachable structure with inner ring and outer ring.

Product Parameters

Product Specification

NF Series

NF200 Series

| Bearing No. | Principal Dimensions(mm) | Basic Load Ratings(KN) | Limited Speed(rpm) | Weight (kg) | ||||||

| d | D | B | rs min | rs1 min | Dynamic(Cr) | Static(Cor) | Grease | Oil | ||

| NF204E | 20 | 47 | 14 | 1 | 0.6 | 17 | 14 | 17000 | 20000 | 0.109 |

| NF205E | 25 | 52 | 15 | 1 | 0.6 | 28 | 27 | 11000 | 14000 | 0.148 |

| NF206E | 30 | 62 | 16 | 1 | 0.6 | 36 | 36 | 8500 | 11000 | 0.22 |

| NF207E | 35 | 72 | 17 | 1.1 | 0.6 | 47 | 48 | 7500 | 9500 | 0.344 |

| NF208E | 40 | 80 | 18 | 1.1 | 1.1 | 52 | 53 | 7000 | 9000 | 0.39 |

| NF209E | 45 | 85 | 19 | 1.1 | 1.1 | 59 | 64 | 6300 | 8000 | 0.52 |

| NF210E | 50 | 90 | 20 | 1.1 | 1.1 | 61 | 69 | 6000 | 7500 | 0.56 |

| NF211E | 55 | 100 | 21 | 1.5 | 1.1 | 80 | 96 | 5300 | 6700 | 0.62 |

| NF212E | 60 | 110 | 22 | 1.5 | 1.5 | 90 | 102 | 5000 | 6300 | 0.84 |

| NF213E | 65 | 120 | 23 | 1.5 | 1.5 | 102 | 118 | 4500 | 5600 | 1.05 |

| NF214E | 70 | 125 | 24 | 1.5 | 1.5 | 112 | 135 | 4300 | 5300 | 1.29 |

| NF215E | 75 | 130 | 25 | 1.5 | 1.5 | 125 | 155 | 4000 | 5000 | 1.45 |

| NF216E | 80 | 140 | 26 | 2 | 2 | 132 | 165 | 3800 | 4800 | 1.74 |

| NF217E | 85 | 150 | 28 | 2 | 2 | 158 | 192 | 3600 | 4500 | 2.08 |

| NF218E | 90 | 160 | 30 | 2 | 2 | 170 | 203 | 3400 | 4300 | 2.5 |

| NF219E | 95 | 170 | 32 | 2.1 | 2.1 | 192 | 214 | 3200 | 4000 | 2.8 |

| NF220E | 100 | 180 | 34 | 2.1 | 2.1 | 208 | 226 | 3000 | 3800 | 3.14 |

| NF221E | 105 | 190 | 36 | 2.1 | 2.1 | 224 | 238 | 2800 | 3600 | 4 |

| NF222E | 110 | 200 | 38 | 2.1 | 2.1 | 239 | 342 | 2600 | 3400 | 5.11 |

| NF224E | 120 | 215 | 40 | 2.1 | 2.1 | 247 | 249 | 2200 | 3000 | 6.32 |

| NF226E | 130 | 230 | 40 | 2.1 | 2.1 | 358 | 372 | 2000 | 2800 | 7.38 |

| NF228E | 140 | 250 | 42 | 2.4 | 2.4 | 302 | 415 | 1800 | 2400 | 9.01 |

NF300 Series

| Bearing No. | Principal Dimensions(mm) | Basic Load Ratings(KN) | Limited Speed(rpm) | Weight (kg) | ||||||

| d | D | B | rs min | rs1 min | Dynamic(Cr) | Static(Cor) | Grease | Oil | ||

| NF303E | 17 | 47 | 14 | 1 | 0.6 | 24.65 | 21.16 | 13000 | 15000 | 0.139 |

| NF304E | 20 | 52 | 15 | 1.1 | 0.6 | 23.1 | 19.2 | 14000 | 17000 | 0.149 |

| NF305E | 25 | 62 | 17 | 1.1 | 1.1 | 38.5 | 35.8 | 9000 | 12000 | 0.24 |

| NF306E | 30 | 72 | 19 | 1.1 | 1.1 | 49.2 | 48.2 | 8000 | 10000 | 0.38 |

| NF307E | 35 | 80 | 21 | 1.5 | 1.1 | 62 | 63.2 | 7000 | 9000 | 0.54 |

| NF308E | 40 | 90 | 23 | 1.5 | 1.5 | 76.8 | 77.8 | 6300 | 8000 | 0.65 |

| NF309E | 45 | 100 | 25 | 1.5 | 1.5 | 93 | 98 | 5600 | 7000 | 0.95 |

| NF310E | 50 | 110 | 27 | 2 | 2 | 105 | 112 | 5300 | 6700 | 1.2 |

| NF311E | 55 | 120 | 29 | 2 | 2 | 128 | 138 | 4800 | 6000 | 1.61 |

| NF312E | 60 | 130 | 31 | 2.1 | 2.1 | 142 | 155 | 4500 | 5600 | 1.94 |

| NF313E | 65 | 140 | 33 | 2.1 | 2.1 | 170 | 188 | 4000 | 5000 | 2.42 |

| NF314E | 70 | 150 | 35 | 2.1 | 2.1 | 195 | 220 | 3800 | 4800 | 2.9 |

| NF315E | 75 | 160 | 37 | 2.1 | 2.1 | 228 | 260 | 3600 | 4500 | 3.59 |

| NF316E | 80 | 170 | 39 | 2.1 | 2.1 | 245 | 270 | 3400 | 4300 | 3.9 |

| NF317E | 85 | 180 | 41 | 3 | 3 | 265 | 280 | 3200 | 4000 | 5.2 |

| NF318E | 90 | 190 | 43 | 3 | 3 | 290 | 320 | 3000 | 3800 | 6.17 |

| NF319E | 95 | 200 | 45 | 3 | 3 | 320 | 350 | 2800 | 3600 | 6.92 |

| NF320E | 100 | 215 | 47 | 3 | 3 | 355 | 380 | 2600 | 3200 | 8.24 |

| NF321E | 105 | 225 | 49 | 3 | 3 | 390 | 420 | 2200 | 3000 | 9.9 |

| NF322E | 110 | 240 | 50 | 3 | 3 | 415 | 470 | 2000 | 2800 | 11.2 |

| NF324E | 120 | 260 | 55 | 3 | 3 | 440 | 552 | 1900 | 2600 | 14.1 |

NF2200 Series

| Bearing No. | Principal Dimensions(mm) | Basic Load Ratings(KN) | Limited Speed(rpm) | Weight (kg) | ||||||

| d | D | B | rs min | rs1 min | Dynamic(Cr) | Static(Cor) | Grease | Oil | ||

| NF2203EM | 17 | 40 | 16 | 0.6 | 0.3 | 24 | 22 | 16000 | 18000 | 0.095 |

| NF2204EM | 20 | 47 | 18 | 1 | 0.6 | 22.2 | 20.3 | 15000 | 18000 | 0.141 |

| NF2205EM | 25 | 52 | 18 | 1 | 0.6 | 23.7 | 22.8 | 10000 | 14000 | 0.168 |

| NF2206EM | 30 | 62 | 20 | 1 | 0.6 | 23.9 | 33.1 | 7500 | 11000 | 0.3 |

| NF2207EM | 35 | 72 | 23 | 1.1 | 0.6 | 49 | 51.2 | 6500 | 9500 | 0.45 |

| NF2208EM | 40 | 80 | 23 | 1.1 | 1.1 | 58.3 | 62 | 6000 | 9000 | 0.49 |

| NF2209EM | 45 | 85 | 23 | 1.1 | 1.1 | 61.4 | 67.8 | 5300 | 8000 | 0.54 |

| NF2210EM | 50 | 90 | 23 | 1.1 | 1.1 | 64.2 | 73.6 | 5000 | 7500 | 0.65 |

| NF2211EM | 55 | 100 | 25 | 1.5 | 1.1 | 75.3 | 87.2 | 4300 | 6700 | 0.77 |

| NF2212EM | 60 | 110 | 28 | 1.5 | 1.5 | 101 | 123 | 4000 | 6300 | 1.09 |

| NF2213EM | 65 | 120 | 31 | 1.5 | 1.5 | 120 | 149 | 3500 | 5600 | 1.55 |

| NF2214EM | 70 | 125 | 31 | 1.5 | 1.5 | 119 | 151 | 3300 | 5300 | 1.7 |

| NF2215EM | 75 | 130 | 31 | 1.5 | 1.5 | 135 | 172 | 3000 | 5000 | 1.8 |

| NF2216EM | 80 | 140 | 33 | 2 | 2 | 148 | 186 | 2800 | 4800 | 2.2 |

| NF2217EM | 85 | 150 | 36 | 2 | 2 | 169 | 218 | 2600 | 4500 | 2.8 |

| NF2218EM | 90 | 160 | 40 | 2 | 2 | 207 | 265 | 2400 | 4300 | 3.6 |

| NF2219EM | 95 | 170 | 43 | 2.1 | 2.1 | 230 | 298 | 2200 | 4000 | 4.3 |

| NF2220EM | 100 | 180 | 46 | 2.1 | 2.1 | 259 | 338 | 2000 | 3800 | 5.99 |

| NF2222EM | 110 | 200 | 53 | 2.1 | 2.1 | 334 | 442 | 1600 | 3400 | 8.7 |

| NF2224EM | 120 | 215 | 58 | 2.1 | 2.1 | 367 | 492 | 1200 | 3000 | 9.55 |

| NF2226EM | 130 | 230 | 64 | 3 | 3 | 395 | 560 | 1000 | 2800 | 11.9 |

RN Series

| Bearing No. | Principal Dimensions(mm) | Basic Load Ratings(KN) | Limited Speed(rpm) | Weight (kg) | ||||

| Grease | Oil | |||||||

| d | Ew | B | Dynamic(Cr) | Static(Cor) | ||||

| RN310EM | 50 | 95 | 27 | 105 | 112 | 5300 | 6700 | 0.79 |

| RN308EM | 40 | 77.5 | 23 | 81 | 87 | 6300 | 8000 | 0.41 |

| RN309EM | 45 | 86.5 | 25 | 93 | 98 | 5600 | 7000 | 0.61 |

| RN307EM | 35 | 68.2 | 21 | 62 | 63.2 | 7000 | 9000 | 0.32 |

| RN228EM | 140 | 221 | 42 | 302 | 415 | 1800 | 2400 | 5.95 |

| RN222EM | 110 | 178.5 | 38 | 278 | 360 | 2600 | 3400 | 3.3 |

| RN220EM | 100 | 160 | 34 | 235 | 302 | 3000 | 3800 | 2.65 |

| RN219EM | 95 | 151.5 | 32 | 208 | 262 | 3200 | 4000 | 2.18 |

| RN208EM | 40 | 70 | 18 | 51.5 | 53 | 7000 | 9000 | 0.27 |

| RN207EM | 35 | 61.8 | 17 | 46.5 | 48 | 7500 | 9500 | 0.2 |

| RN206EM | 30 | 53.5 | 16 | 36 | 35.5 | 8500 | 11000 | 0.11 |

| RN205EM | 25 | 45 | 15 | 27.5 | 26.8 | 11000 | 14000 | 0.09 |

| RN204EM | 17 | 40 | 14 | 25.8 | 24 | 12000 | 16000 | 0.08 |

| RN203EM | 17 | 40 | 12 | 19.3 | 17 | 10000 | 11000 | 0.08 |

| RN312EM | 60 | 113 | 31 | 142 | 155 | 4500 | 5600 | 1.11 |

| RN313EM | 65 | 121.5 | 33 | 170 | 188 | 4000 | 5000 | 1.57 |

| RN328EM | 140 | 260 | 62 | 545 | 690 | 1600 | 2000 | 13.2 |

RNU Series

| Bearing No. | Principal Dimensions(mm) | Basic Load Ratings(KN) | Limited Speed(rpm) | Weight (kg) | ||||

| Fw | D | B | Dynamic(Cr) | Static(Cor) | Grease | Oil | ||

| RNU309E | 58.5 | 100 | 25 | 93 | 98 | 5600 | 7000 | 0.79 |

| RNU310E | 65 | 110 | 27 | 105 | 112 | 5300 | 6700 | 1.01 |

| RNU311E | 70.5 | 120 | 29 | 128 | 138 | 4800 | 6000 | 1.5 |

| RNU308E | 53.5 | 90 | 23 | 76.8 | 77.8 | 6300 | 8000 | 0.48 |

| RNU307E | 46.2 | 80 | 21 | 62 | 63.2 | 7000 | 9000 | 0.4 |

| RNU306E | 42 | 72 | 19 | 49.2 | 48.2 | 8000 | 10000 | 0.32 |

| RNU218E | 107 | 160 | 30 | 172 | 215 | 3400 | 4300 | 2.07 |

| RNU305E | 35 | 62 | 17 | 38.5 | 35.8 | 9000 | 12000 | 0.2 |

| RNU214E | 84.5 | 125 | 24 | 112 | 135 | 4300 | 5300 | 0.89 |

| RNU210E | 60.4 | 90 | 20 | 61.2 | 68.2 | 6000 | 7500 | 0.43 |

| RNU212E | 73 | 110 | 22 | 89.8 | 102 | 5000 | 6300 | 0.78 |

| RNU209E | 55 | 85 | 19 | 58.5 | 63.8 | 6300 | 8000 | 0.41 |

| RNU208E | 50 | 80 | 18 | 51.5 | 53 | 7000 | 9000 | 0.25 |

Company Profile

HangZhou solarich machinery Co., Ltd. is a professional manufacturer of bearings, We can design and manufacture single-row ball slewing bearings, double-row ball slewing bearings, three-row roller slewing bearings, ball combination slewing bearings, crossed roller bearings, crossed tapered roller bearings Bearings, slewing drives and custom bearings.

Subordinate factories use high-quality chrome steel and stainless steel as raw materials, specializing in the design, development and manufacture of deep groove ball bearings, stainless steel bearings, stainless steel outer ball bearings , tapered bearings , cylindrical bearings, needle bearing , thrust bearing , bearing housing and non-standard bearings.

Adhering to the business philosophy of “Quality and Integrity”, we will continue to provide excellent bearings and high-quality services to serve global customers.

Our Advantages

With a professional team and advanced manufacturing technology, it is in a leading position in the research and development of slewing rings and customized bearings, with reasonable design structure, light weight, strong bearing capacity and strong versatility. Bearing diameters range from 200 to 15000mm, with accuracies covering P0, P6 and P5 grades. Our slewing rings, precision bearings and custom bearings are used in a wide range of industries including construction, engineering, mining, marine, chemical, wind turbines, medical equipment etc.

Solutions

Playground Equipment

Slewing bearing can provide excellent performance experience and safety guarantee for amusement equipment, and the durability of slewing bearing is also the main concern of technical engineers. For more than 20 years, slewing bearing solutions have been used in many key applications of large amusement equipment. reflect.

We designed the cross-sectional area to remain the same as the raceway center distance increased, and the slewing ring achieves better dynamic capabilities with less mass.

Key advantages include:

* Lighter weight

* Save spaighter weightce

* Long life and lower maintenance costs

* Better stiffness

* Better lubrication in extreme conditions

Medical Device

With the comprehensive development of scientific and technological strength, the social economyu has been improved faster, and the medical equipment has also been comprehensively improved.

Mining & construction machinery

Mining machinery and heavy construction machinery industry uses a range of different types of highly specialized mobile machinery. . The places where mining machinery and construction machinery are active are mostly mining sites such as mountains and deserts that are far away from ordinary human life. These heavy machinery work in the harshest environments and require continuous low-friction work without reducing load capacity and minimum. assembly and adjustment time. Solving the bearing heating problem caused by the large exciting force, high vibration frequency and continuous operation of vibratory rollers for users has become the focus of the work. Mineral crushing machinery, cutting machinery, screening machinery, loading machinery, conveying machinery and other equipment in the use environment of bearings, users desire products with robustness, durability and high reliability to resist these harsh working conditions.

Transportation vehicle

Metric and inch needle roller bearings have various structural types, mainly including open drawn cup needle roller bearings, closed drawn cup needle roller bearings, needle roller bearings with inner ring and needle roller bearings without inner ring/without inner ring Cage needle roller bearings, caged and cageless needle roller bearings. Widely used in automobiles, motorcycles, mopeds, power tools, textiles, agricultural machinery, printing machinery, construction machinery, automatic instruments and other fields.

Automatic machinery

Industrial robot bearings mainly include 2 categories: 1 is thin-walled bearings, and the other is crossed cylindrical roller bearings. In addition, there are harmonic reducer bearings, linear roller bearings, spherical plain bearings, etc. Bearings with good performance have large bearing capacity, good rigidity, high rotation precision and easy installation.

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer?

A: We are bearing manufacturer.

Q: How do you control quality of bearing?

A: All products and services passed ISO9001-2008 Quality Certificate.

Q: What is the MOQ?

A: It depends on the bearing type. You can send inquiry or send e-mail for more information.

Q: How about the package?

A: Industrial packing in general condition (Plastic tube+ carton+ pallet). Accept design package when OEM.

Q: How long is the delivery time?

A: The lead time for sample orders is 3-5 days, for bulk orders is 5-15 days., depends on the model and quantity.

Q: How about the shipping?

A: We can arrange the shipment or you may have the forwarder.

Q: Is sample avaiable?

A: Yes, sample order is acceptable.

Q: Can we use our own LOGO or design on bearings?

A: Yes. OEM is acceptable. We can design the bearing with your requirements and use your own LOGO and package design.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Material: | Bearing Steel |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Advancements in Tapered Roller Bearing Technology

Tapered roller bearing technology has undergone significant advancements over the years, driven by the demands of modern industrial applications and the pursuit of enhanced performance, efficiency, and durability. These advancements have led to innovations in design, materials, manufacturing processes, and lubrication. Here are some key insights into the advancements in tapered roller bearing technology:

- Advanced Bearing Materials:

Manufacturers are exploring new materials and alloy compositions to improve bearing strength, fatigue resistance, and high-temperature performance. Specialized coatings and surface treatments are applied to enhance corrosion resistance and reduce friction.

- Optimized Design and Geometry:

Modern design techniques, such as computer-aided modeling and simulation, allow for the optimization of bearing geometry and internal structures. This results in improved load distribution, reduced stress concentrations, and enhanced overall performance.

- Improved Cage Designs:

Cage designs have evolved to ensure better roller guidance, reduced friction, and minimized wear. Innovative cage materials and shapes enhance lubricant flow and promote efficient operation, especially at high speeds.

- Enhanced Lubrication Systems:

Advancements in lubrication technology have led to the development of specialized lubricants and lubrication systems. These solutions offer better protection against wear, reduce friction, and ensure consistent lubrication even in challenging operating conditions.

- Precision Manufacturing Techniques:

Modern manufacturing methods, such as precision grinding and superfinishing, allow for tighter tolerances and improved surface finishes. This contributes to smoother rolling contact, reduced vibration, and lower noise levels.

- Integrated Sensors and Monitoring:

Advances in sensor technology enable the integration of condition monitoring systems within tapered roller bearings. These sensors provide real-time data on factors like temperature, vibration, and lubrication, allowing for predictive maintenance and performance optimization.

- Customization and Application-Specific Solutions:

Manufacturers offer more customization options to cater to diverse industrial applications. This includes bearings optimized for specific operating conditions, load requirements, and environmental challenges.

- Digitalization and Industry 4.0:

The integration of tapered roller bearing data into digital platforms aligns with the principles of Industry 4.0. Remote monitoring, predictive analytics, and digital twins are used to enhance maintenance strategies and maximize bearing lifespan.

- Energy Efficiency Focus:

Advancements in tapered roller bearing technology align with global efforts to improve energy efficiency. Reduced friction, optimized designs, and efficient lubrication contribute to overall equipment energy savings.

- Sustainability and Eco-Friendly Solutions:

Manufacturers are exploring sustainable materials and manufacturing processes to reduce the environmental impact of bearing production. Eco-friendly lubricants and packaging solutions are also gaining attention.

Overall, advancements in tapered roller bearing technology continue to drive innovation across industries, providing solutions that meet the evolving needs of modern machinery and contribute to improved performance, reliability, and sustainability.

What is the impact of proper lubrication on the performance and lifespan of cylindrical roller bearings?

Proper lubrication plays a crucial role in the performance and lifespan of cylindrical roller bearings. Lubrication is essential for reducing friction, minimizing wear, dissipating heat, and preventing corrosion. Let’s explore the impact of proper lubrication in more detail:

- Friction Reduction:

Proper lubrication forms a thin film of lubricant between the rolling elements and raceways of cylindrical roller bearings. This lubricant film separates the surfaces and reduces direct metal-to-metal contact. As a result, friction and sliding resistance are significantly reduced. The reduction in friction helps to minimize energy loss, improve efficiency, and reduce wear on the bearing components.

- Wear Prevention:

Lubrication creates a protective barrier between the rolling elements and raceways, preventing excessive wear. The lubricant film prevents metal-to-metal contact and acts as a cushion, absorbing shock and distributing the load evenly. By reducing wear, proper lubrication helps to prolong the lifespan of cylindrical roller bearings, ensuring reliable performance over an extended period.

- Heat Dissipation:

During operation, cylindrical roller bearings generate heat due to friction. Proper lubrication helps dissipate this heat by carrying it away from the bearing surfaces. The lubricant absorbs and transfers the heat, preventing excessive temperature buildup that could lead to premature failure. Effective heat dissipation through proper lubrication helps maintain the bearing’s operational stability and prevents thermal damage.

- Prevention of Corrosion:

Lubrication acts as a protective layer, preventing the direct contact of moisture or contaminants with the bearing surfaces. This barrier helps to inhibit corrosion and the formation of rust on the bearing components. By keeping the surfaces clean and protected, proper lubrication aids in maintaining the integrity and longevity of cylindrical roller bearings, especially in challenging environments.

- Noise Reduction:

Proper lubrication contributes to reducing noise and vibration in cylindrical roller bearings. The lubricant film acts as a cushion, damping the vibrations and reducing the generation of noise during operation. This is particularly important in applications where noise reduction is critical, such as precision machinery or equipment operating in quiet environments.

- Contamination Control:

Proper lubrication helps in controlling and minimizing the ingress of contaminants into cylindrical roller bearings. The lubricant forms a barrier that helps prevent the entry of dirt, dust, and other particles that could lead to premature wear or damage. By maintaining cleanliness, proper lubrication enhances the overall performance and reliability of the bearing.

In summary, proper lubrication is essential for optimizing the performance and extending the lifespan of cylindrical roller bearings. It reduces friction, minimizes wear, dissipates heat, prevents corrosion, reduces noise, and controls contamination. Bearing manufacturers and operators must follow recommended lubrication practices, including selecting the appropriate lubricant type and viscosity, ensuring proper lubricant replenishment, and adhering to scheduled maintenance intervals, to maximize the benefits of lubrication and ensure the long-term reliability of cylindrical roller bearings.

Can you describe the load-carrying capacity and load ratings of cylindrical roller bearings?

Cylindrical roller bearings have specific load-carrying capacity and load rating characteristics that determine their performance under different operating conditions. Let’s delve into the details of load-carrying capacity and load ratings for cylindrical roller bearings:

- Radial Load-Carrying Capacity:

Cylindrical roller bearings are primarily designed to handle radial loads, which are forces applied perpendicular to the shaft. They have a high radial load-carrying capacity due to the arrangement of cylindrical rollers and their large contact area with the raceways. The load is distributed evenly along the length of the rollers, allowing cylindrical roller bearings to support heavy machinery components and withstand substantial radial forces.

- Axial Load-Carrying Capacity:

While cylindrical roller bearings are primarily intended for radial loads, they can also accommodate moderate axial loads, which are forces applied parallel to the shaft. The axial load-carrying capacity of cylindrical roller bearings is limited compared to their radial load capacity. Therefore, for applications with predominantly axial loads, other types of bearings, such as thrust bearings, should be considered.

- Dynamic Load Rating:

The dynamic load rating is a key parameter that indicates the maximum load a bearing can withstand under specific operating conditions without suffering premature fatigue failure. It is defined as the constant radial load (or radial equivalent load) that a group of identical bearings can theoretically endure for a rating life of one million revolutions. The dynamic load rating is specified by the bearing manufacturer and is expressed in Newtons (N) or pounds-force (lbf).

- Static Load Rating:

The static load rating of a cylindrical roller bearing represents the maximum radial load it can sustain without exhibiting excessive permanent deformation. Unlike the dynamic load rating, which considers the fatigue life of the bearing, the static load rating focuses on the bearing’s ability to withstand a static load for an extended period without experiencing plastic deformation or other permanent damage. Similar to the dynamic load rating, the static load rating is provided by the manufacturer and is expressed in Newtons (N) or pounds-force (lbf).

- Load Rating Calculation:

The load ratings of cylindrical roller bearings are determined through standardized calculation methods defined by international standards organizations such as ISO (International Organization for Standardization) and ABMA (American Bearing Manufacturers Association). These calculations take into account factors such as bearing dimensions, geometry, material properties, and operating conditions to establish the dynamic and static load ratings for a specific bearing model.

- Application Considerations:

When selecting cylindrical roller bearings for a particular application, it is crucial to consider the expected load requirements, load orientation, and operating conditions. The calculated load ratings should be compared to the actual loads that the bearing will experience in the application to ensure that the chosen bearing can safely and reliably support the anticipated loads throughout its service life.

In conclusion, cylindrical roller bearings have a high radial load-carrying capacity and can accommodate moderate axial loads. The dynamic and static load ratings provided by the manufacturer serve as important parameters for assessing the bearing’s load-carrying capability and determining its suitability for specific applications.

editor by CX 2024-04-25