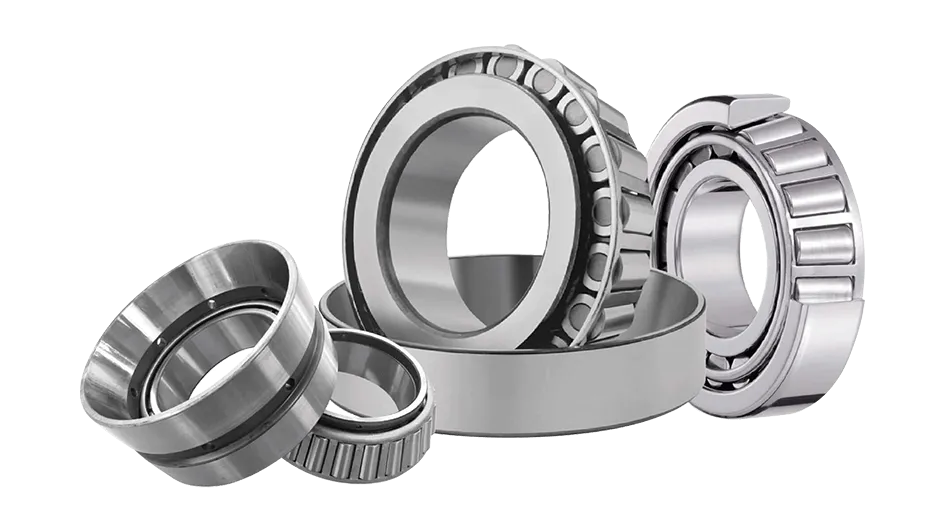

Product Description

The Spherical roller bearings are between the inner ring with 2 rolling roads and the outer ring with the roller.

The Spherical roller bearing has 2 rollers, which mainly bear the radial load, and can also bear the axial load in any direction. It has high radial load capacity, which is particularly suitable for working under heavy load or vibration load, but cannot withstand pure axial loads. This type of bearing is a spherical shape, so its heart adjustment performance is good and can compensate the same axis error.

|

New Item |

Old Item |

Structure |

Specifications (dxDxT)mm |

Weight/kg |

|

22205 |

3505 |

MB/CA/CC/EK/CK/CMW33 |

25×52×18 |

0.18 |

|

22206 |

3506 |

MB/CA/CC/EK/CK/CMW33 |

30×62×20 |

0.3 |

|

22207 |

3507 |

MB/CA/CC/EK/CK/CMW33 |

35x72x23 |

0.43 |

|

22208 |

3508 |

MB/CA/CC/E/K/CK/CMW33 |

40X80X23 |

0.55 |

|

22209 |

3509 |

MB/CA/CC/E/K/CK/CMW33 |

45X85X23 |

0.59 |

|

22210 |

3510 |

MB/CA/CC/E/K/CK/CMW33 |

50X90X23 |

0.64 |

|

22211 |

3511 |

MB/CA/CC/E/K/CK/CMW33 |

55X100X25 |

0.88 |

|

22212 |

3512 |

MB/CA/CC/E/K/CK/CMW33 |

60X110X28 |

1.19 |

|

22213 |

3513 |

MB/CA/CC/E/K/CK/CMW33 |

65X120X31 |

1.6 |

|

22214 |

3514 |

MB/CA/CC/E/K/CK/CMW33 |

70X125X31 |

1.68 |

|

22215 |

3515 |

MB/CA/CC/E/K/CK/CMW33 |

75X130X31 |

1.75 |

|

22216 |

3516 |

MB/CA/CC/E/K/CK/CMW33 |

80X140X33 |

2.12 |

|

22217 |

3517 |

MB/CA/CC/E/K/CK/CMW33 |

85X150X36 |

2.79 |

|

22218 |

3518 |

MB/CA/CC/E/K/CK/CMW33 |

90X160X40 |

3.78 |

|

22219 |

3519 |

MB/CA/CC/E/K/CK/CMW33 |

95X170X43 |

4.31 |

|

22220 |

3520 |

MB/CA/CC/E/K/CK/CMW33 |

100X180X46 |

5.06 |

|

22222 |

3522 |

MB/CA/CC/E/K/CK/CMW33 |

110X200X53 |

7.4 |

|

22224 |

3524 |

MB/CA/CC/E/K/CK/CMW33 |

120X215X58 |

9.267 |

|

22226 |

3526 |

MB/CA/CC/E/K/CK/CMW33 |

130X230X64 |

11.5 |

|

22228 |

3528 |

MB/CA/CC/E/K/CK/CMW33 |

140X250X68 |

14.5 |

|

22230 |

3530 |

MB/CA/CC/E/K/CK/CMW33 |

150X270X73 |

18.4 |

|

22232 |

3532 |

MB/CA/CC/E/K/CK/CMW33 |

160X260X80 |

22.3 |

|

22234 |

3534 |

MB/CA/CC/E/K/CK/CMW33 |

170X310X86 |

28.7 |

|

22236 |

3536 |

MB/CA/CC/E/K/CK/CMW33 |

180X320X86 |

30.5 |

|

22238 |

3538 |

MB/CA/CC/E/K/CK/CMW33 |

190X320X92 |

35.55 |

|

22240 |

3540 |

MB/CA/CC/E/K/CK/CMW33 |

200X360X98 |

44.7 |

|

22244 |

3544 |

MB/CA/CC/E/K/CK/CMW33 |

220X400X108 |

63 |

|

22248 |

3548 |

MB/CA/CC/E/K/CK/CMW33 |

240X440X120 |

83.2 |

|

22252 |

3552 |

MB/CA/CC/E/K/CK/CMW33 |

260X480X130 |

105 |

|

22256 |

3556 |

MB/CA/CC/E/K/CK/CMW33 |

280X500X130 |

126 |

|

22260 |

3560 |

MB/CA/CC/E/K/CK/CMW33 |

300X540X140 |

143 |

|

22306 |

3606 |

MB/CA/CC/E/K/CK/CMW33 |

30x70x22 |

0.37 |

|

22307 |

3607 |

MB/CA/CC/E/K/CK/CMW33 |

35x80x31 |

0.75 |

|

22308 |

3608 |

MB/CA/CC/E/K/CK/CMW33 |

40x90x33 |

1.07 |

|

22309 |

3609 |

MB/CA/CC/E/K/CK/CMW33 |

45x90x33 |

1.4 |

|

22310 |

3610 |

MB/CA/CC/E/K/CK/CMW33 |

50x110x40 |

1.83 |

|

22311 |

3611 |

MB/CA/CC/E/K/CK/CMW33 |

55x120x43 |

2.4 |

|

22312 |

3612 |

MB/CA/CC/E/K/CK/CMW33 |

60x130x46 |

2.88 |

|

22313 |

3613 |

MB/CA/CC/E/K/CK/CMW33 |

65x140x48 |

3.52 |

|

22314 |

3614 |

MB/CA/CC/E/K/CK/CMW33 |

70x150x51 |

4.21 |

|

22315 |

3615 |

MB/CA/CC/E/K/CK/CMW33 |

75x160x55 |

5.47 |

|

22316 |

3616 |

MB/CA/CC/E/K/CK/CMW33 |

80x170x58 |

6.19 |

|

22317 |

3617 |

MB/CA/CC/E/K/CK/CMW33 |

85x180x60 |

7.5 |

|

22318 |

3618 |

MB/CA/CC/E/K/CK/CMW33 |

90x190x64 |

8.96 |

|

22319 |

3619 |

MB/CA/CC/E/K/CK/CMW33 |

95x200x67 |

9.93 |

|

22320 |

3620 |

MB/CA/CC/E/K/CK/CMW33 |

100x215x73 |

13 |

|

22322 |

3622 |

MB/CA/CC/E/K/CK/CMW33 |

110x240x80 |

17.95 |

|

22324 |

3624 |

MB/CA/CC/E/K/CK/CMW33 |

120x246x80 |

22.4 |

|

22326 |

3626 |

MB/CA/CC/E/K/CK/CMW33 |

130x280x93 |

28.2 |

|

22328 |

3628 |

MB/CA/CC/E/K/CK/CMW33 |

140x300x102 |

35.12 |

|

22330 |

3630 |

MB/CA/CC/E/K/CK/CMW33 |

150x320x108 |

43.7 |

|

22332 |

3632 |

MB/CA/CC/E/K/CK/CMW33 |

160x340x114 |

52.2 |

|

22334 |

3634 |

MB/CA/CC/E/K/CK/CMW33 |

170x360x120 |

60.7 |

|

22336 |

3636 |

MB/CA/CC/E/K/CK/CMW33 |

180x380x126 |

70 |

|

22338 |

3638 |

MB/CA/CC/E/K/CK/CMW33 |

190x400x132 |

81 |

|

22340 |

3640 |

MB/CA/CC/E/K/CK/CMW33 |

200x420x138 |

94 |

ZheJiang Haina Bearing Co., Ltd. is an integrated company of industry and trade. Since its establishment, it has been committed to the research and development, production, and sales of high-end 7 types of tapered roller bearings, British non-standard bearings, deep groove ball bearings, and outer spherical bearings. We can customize and adjust various types of bearings according to customer needs. The products are widely applicablein fields such as automobiles, mines, chemicals, metallurgy, reducers, engineering machinery, agricultural machinery, and electric motors.

Our company has advanced testing equipment, forming a production model of product serialization and mass production. We have a group of experienced and skilled management personnel, who have introduced advanced production equipment and measuringand testing equipment. From the purchase of bearing raw materials to the delivery of finished products, we strictly control the entire process, ensuring the quality of the products.The products have the characteristics of precision, low noise, high load-bearing capacity and long service life.

1. Your factory how to control the quality?

A: All bearing parts before the production and the production process, strict inspection by 100%, including crack detection, roundness, hardness,

roughness,and the geometry size, all bearing meet ISO international standard.

2. Can you tell me the bearing material?

A: We have chrome steel GCR15, stainless steel, ceramics and other materials.

3. How long is your delivery time?

A: If the goods are in stock, usually 5 to 10 days, if the goods are no stock for 15 to 20 days, according to the quantity to determine the time.

4. OEM and custom you can receive?

A: Yes, accept OEM, can also be customized according to samples or drawings for you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Model No.: | 22326 22328 22330 22332 22334 |

|---|---|

| OEM: | Acceptable |

| Quality: | P0, P2, P4, P5, P6 |

| Number of Row: | Double Rows |

| Single Row ID Size Range: | 130-170mm |

| Single Row Od Size Range: | 280-360mm |

| Samples: |

US$ 53.59/Piece

1 Piece(Min.Order) | |

|---|

What are the Challenges Associated with Thermal Expansion in Tapered Roller Bearings?

Thermal expansion presents several challenges in tapered roller bearings, particularly in industrial and high-speed applications. As the bearing components heat up during operation, they expand, which can impact the bearing’s performance, longevity, and overall operation. Here are the challenges associated with thermal expansion in tapered roller bearings:

- Internal Clearance Reduction:

As the bearing components heat up, their dimensions increase due to thermal expansion. This reduction in internal clearance can lead to increased friction, higher operating temperatures, and even binding of the rolling elements.

- Lubrication Concerns:

Thermal expansion can affect the distribution and viscosity of the lubricant within the bearing. If the lubricant thins out due to temperature rise, it may not provide adequate protection against friction and wear, potentially leading to premature failure.

- Increased Friction and Wear:

With reduced internal clearance and potential changes in lubrication properties, the bearing is more susceptible to increased friction and wear. This can result in accelerated wear of the rolling elements, raceways, and cage.

- Higher Operating Temperatures:

Thermal expansion contributes to elevated operating temperatures within the bearing assembly. Excessive heat generation can degrade the lubricant, weaken bearing materials, and reduce overall efficiency.

- Alignment Issues:

Temperature-related expansion can lead to misalignment between bearing components, causing uneven loading and potential damage to the rollers and raceways. This misalignment can also lead to increased vibration and noise.

- Variability in Fit and Clearance:

Components within the bearing may expand at different rates due to variations in material properties. This can result in changes in fit and clearance between components, affecting the overall stability and performance of the bearing.

- Impact on Preload:

If a bearing is preloaded to eliminate internal clearance, thermal expansion can significantly affect preload values. This can lead to altered load distribution, increased stress on components, and potential bearing damage.

- Performance Inconsistencies:

Thermal expansion can introduce inconsistencies in bearing performance, especially during transient operating conditions where temperature changes occur rapidly.

- Limitations in High-Speed Applications:

In high-speed applications, the rapid temperature rise due to friction and heat generation can exacerbate the challenges of thermal expansion, necessitating careful design and lubrication strategies.

- Design and Material Considerations:

Manufacturers must carefully consider the materials and design aspects of tapered roller bearings to account for thermal expansion effects. This may involve selecting materials with suitable thermal properties and optimizing internal clearances.

Managing thermal expansion challenges requires a comprehensive approach that involves proper bearing design, lubrication strategies, and monitoring of operating conditions. Addressing these challenges ensures that tapered roller bearings can perform optimally and reliably in various applications.

Can you provide examples of industries or equipment that frequently use cylindrical roller bearings?

Cylindrical roller bearings are widely used in various industries and equipment where rotational motion is involved. Their design and characteristics make them suitable for numerous applications that require high radial load capacity, moderate axial load capacity, and the ability to accommodate misalignment. Let’s explore some examples of industries and equipment that frequently utilize cylindrical roller bearings:

- Automotive Industry:

The automotive industry extensively uses cylindrical roller bearings in various components such as wheel hubs, transmissions, engines, steering systems, and differentials. These bearings provide support for rotating shafts and help withstand radial loads encountered during vehicle operation. They contribute to the smooth and efficient functioning of critical automotive systems.

- Mining and Construction:

In the mining and construction sectors, cylindrical roller bearings are crucial for heavy-duty applications. They are commonly found in equipment such as conveyor systems, crushers, pulverizers, excavators, and loaders. These bearings are designed to handle high radial loads and provide reliable performance in demanding environments characterized by dust, dirt, and heavy vibrations.

- Power Generation:

Cylindrical roller bearings are extensively used in power generation equipment, including turbines, generators, and electric motors. They play a vital role in supporting rotating shafts and providing smooth operation under high-speed and high-temperature conditions. These bearings are designed to handle significant radial loads, ensuring reliable and efficient power generation.

- Steel and Metal Processing:

The steel and metal processing industry relies on cylindrical roller bearings in various applications, including rolling mills, continuous casting machines, and metal cutting equipment. These bearings are capable of withstanding heavy loads, high temperatures, and harsh operating conditions encountered in metal processing operations.

- Pulp and Paper:

In the pulp and paper industry, cylindrical roller bearings are found in paper machines, rollers, and rotary kilns. They provide support for rotating drums, rolls, and shafts, ensuring smooth and reliable operation during the paper production process. These bearings are designed to withstand the high loads and continuous operation associated with paper manufacturing.

- Machine Tools:

Cylindrical roller bearings are widely used in machine tools such as lathes, milling machines, grinders, and machining centers. They provide precise support for rotating spindles and shafts, enabling accurate and efficient metal cutting operations. These bearings contribute to the precision and reliability required in the machining industry.

- Textile Machinery:

The textile industry utilizes cylindrical roller bearings in various textile machinery, including spinning frames, looms, and winding machines. These bearings support rotating components and help maintain the tension and smooth movement of yarns and fibers during the textile production process. They are designed to withstand high speeds and provide reliable performance in textile manufacturing operations.

These are just a few examples of industries and equipment that frequently rely on cylindrical roller bearings. Their versatility, load-carrying capacity, and ability to operate in diverse environments make them suitable for a wide range of applications across numerous sectors.

How do cylindrical roller bearings differ from other types of roller bearings?

Cylindrical roller bearings possess distinct characteristics that set them apart from other types of roller bearings. Let’s examine the key differences between cylindrical roller bearings and other common roller bearing types:

- Design and Structure:

Cylindrical roller bearings feature cylindrical rollers that have a high length-to-diameter ratio. This design allows them to accommodate high radial loads and moderate thrust loads. In contrast, other types of roller bearings, such as spherical roller bearings or tapered roller bearings, have different roller shapes and configurations tailored for specific load and application requirements.

- Load Capacity:

Cylindrical roller bearings excel in handling radial loads. Their cylindrical roller arrangement and large contact area with the raceways enable them to distribute loads evenly along the rollers’ length. This characteristic makes cylindrical roller bearings suitable for applications where the primary load is radial. In comparison, other roller bearing types may be better suited for applications with different load orientations or combinations of radial and axial loads.

- Thrust Load Capability:

While cylindrical roller bearings can accommodate moderate axial loads, they are primarily designed for radial load-carrying capacity. On the other hand, thrust roller bearings, such as spherical roller thrust bearings or tapered roller thrust bearings, are specifically designed to handle predominantly axial loads. These thrust bearings have different roller arrangements and structures optimized for axial load resistance.

- Internal Clearance:

Cylindrical roller bearings offer a range of internal clearances, which is the space between the rolling elements and raceways when no external load is applied. The internal clearance affects factors such as running accuracy, thermal expansion, and the ability to accommodate misalignment or axial displacement. In contrast, other roller bearing types may have different clearance options or incorporate specific features, such as preloading, to optimize performance in their respective applications.

- Application Diversity:

Cylindrical roller bearings find extensive use in various machinery applications, including electric motors, gearboxes, pumps, and compressors. However, other roller bearing types have their own advantages and are commonly employed in specific industries or applications. For instance, needle roller bearings are suitable for applications with limited radial space, while crossed roller bearings are commonly used in precision machinery that requires high positioning accuracy.

- Operating Speed:

Cylindrical roller bearings can operate at high speeds, depending on their design and internal clearance. Manufacturers provide speed ratings and guidelines to ensure proper selection and operation within the bearing’s speed limits. Other roller bearing types may have different speed capabilities based on their specific design features, such as the shape of the rollers, cage design, or lubrication requirements.

Understanding the differences between cylindrical roller bearings and other types of roller bearings is crucial for selecting the appropriate bearing for a given application. Factors such as load requirements, load orientation, speed, space limitations, and environmental conditions should be carefully considered to ensure optimal bearing performance and longevity.

editor by CX 2024-04-25