Product Description

KOYO CZPT CZPT NSK NJ2211E NJ2212E NJ2213E NJ2214E NJ2215E NJ2216E NJ2217E NJ2218E NJ2219E NJ2220E NJ2222 NJ2224 NJ2226 NF202 NF203 Cylindrical Roller Bearing

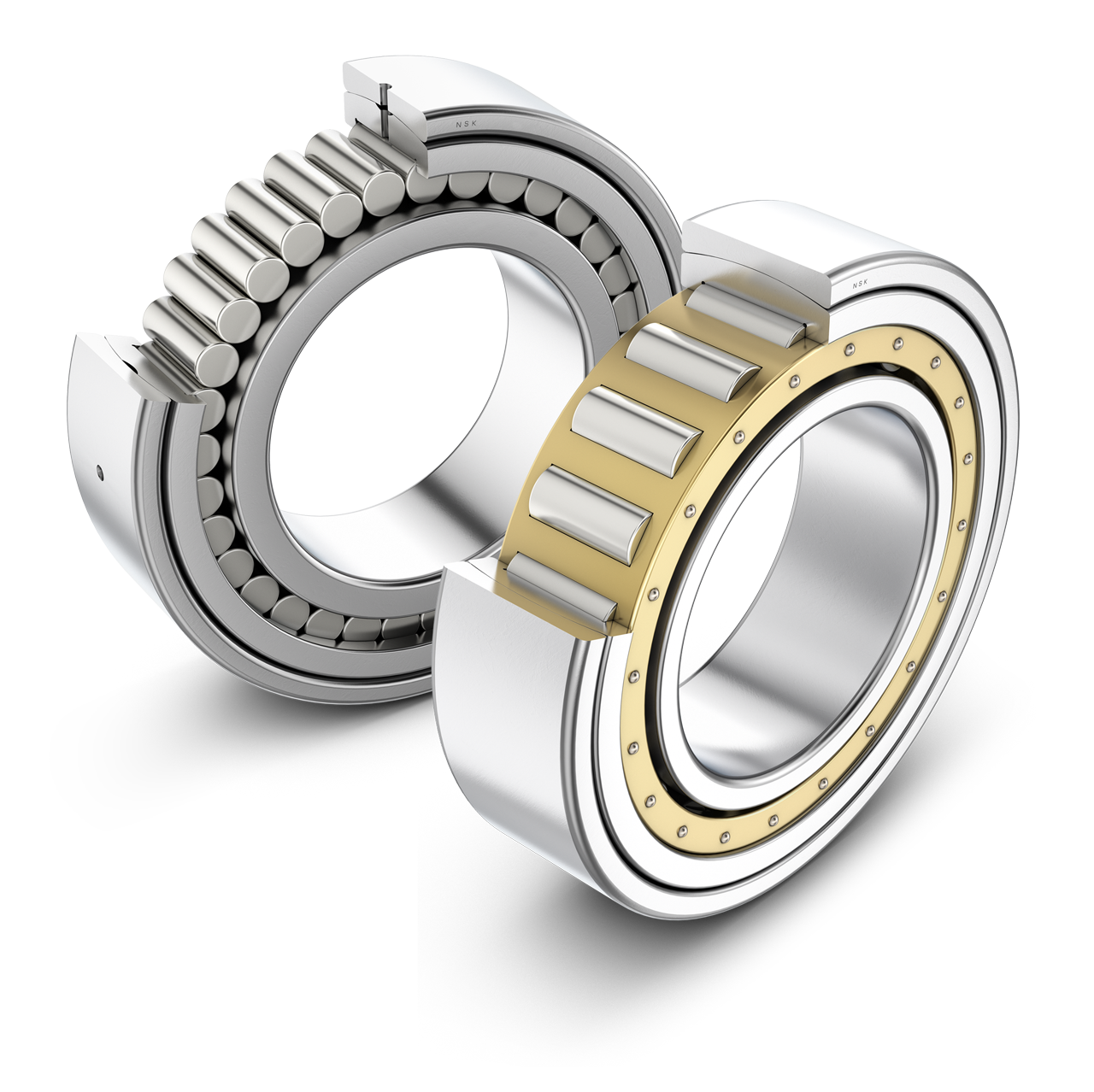

Feature: Cylindrical roller bearing

Single row cylindrical roller bearing feature:

Tape NU and type N allow shaft moving in axial direction within limits,applicable to use as free end.

Type NJ and type NF can carry certain extent one-way axial load.Type NUP and type NH can carry certain extent both-way axial load.

Main dimension of type E cylindrical roller bearing coordinate with standard, and through modifying interior specification to increase nominal load.

Double row cylindrical roller bearing feature:

Double row cylindrical roller bearing have cylindrical hole and tapered hole type,tapered bore bearing can get needed internal clearance by self-aligning the depth of thrusting in.

Besides,there are bearing whose outer ring with oil hole and oil tank,it’s nominal type code has a post position assistant code “W”.

The type bearing has strong fixity resisting reversal load,mainly applicable to chief shaft of machine tool,etc.

Types of Cylindrical roller bearing

N series cylindrical roller bearing design The inner ring has 2 integral flanges and the outer ring is without flanges. Axial displacement of the shaft with respect to the housing can be accommodated in both directions within the bearing itself. The bearings are therefore used as non-locating bearings.

NU series cylindrical roller bearing design The outer ring of bearings of the NU design has 2 integral flanges and the inner ring is without flanges. Axial displacement of the shaft with respect to the housing can be accommodated in both directions within the bearing itself.

NJ series cylindrical roller bearing design The outer ring has 2 integral flanges and the inner ring 1 integral flange. The bearings are therefore suitable for the axial location of a shaft in 1 direction.

NF series cylindrical roller bearing design The outer ring has 1 integral flange and the inner ring 2 integral flanges.

NP series cylindrical roller bearing design The outer ring has 1 integral flange and 1 non-integral flange in the form of a loose flange ring and the inner ring 2 integral flanges.

NUP series cylindrical roller bearing design The outer ring has 2 integral flanges and the inner ring 1 integral flange and 1 non-integral flange in the form of a loose flange ring. The bearings can be used as locating bearings, i.e. they can provide axial location for a shaft in both directions.

RN series cylindrical roller bearing design No outer ring and the inner ring 2 integral flanges.

Cylindrical roller bearing Specification:

| Seals Types | OPEN |

| Vibration Level | Z1V1,Z2V2,Z3V3 |

| Clearance | C2,C0,C3,C4,C5 |

| Tolerance Codes | ABEC-1,ABEC-3,ABEC-5 |

| Materral | GCr15-China/AISI52100-USA/Din100Cr6-Germany |

| MOQ | 1Set at least |

| Delivery Time | 15-45 days after contract |

| Payment Terms | TT/PAPAL/WESTERN UNION |

| Package | Tube package+outer carton+pallets;Single box+outer carton+pallets;Tube pavkge+middle box+outer carton+pallets;According to your requirement |

A Part of Cylindrical Roller Bearings:

| N/Nu/NF/Nj/Nup/Ncl/Rn/Rnu Series | |||

| NU207(M) | NJ202(E/EM) | NF202 | NUP210E |

| NU208(M) | NJ203(E/EM) | NF203 | NUP211E |

| NU210(M) | NJ204(E/EM) | NF204 | NUP212E |

| NU211(M) | NJ205(E/EM) | NF205 | NUP213E |

| NU212(M) | NJ206(E/EM) | NF206 | NUP214E |

| NU213(M) | NJ207(E/EM) | NF207 | NUP215E |

| NU214(M) | NJ208(E/EM) | NF208 | NUP216E |

| NU215(M) | NJ209(E/EM) | NF209 | NUP217E |

| NU216(M) | NJ310EM | NF306(EM/ETN) | NUP218E |

| NU217(M) | NJ311EM | NF307(EM/ETN) | NUP219E |

| NU218(M) | NJ313EM | NF308(EM/ETN) | NUP2205E |

| NU219(M) | NJ313EM | NF309(EM/ETN) | NUP2206E |

| NU220(M) | NJ314EM | NF2210EM | NUP2207E |

| NU221(M) | NJ315EM | NF2211EM | NUP2208E |

| NU222(M) | NJ316EM | NF2212EM | NUP2209E |

| NU224(M) | NJ317EM | NF2213EM | NUP2210E |

| NU226(M) | NJ318EM | NF2214EM | NUP2211E |

| NU228(M) | NJ319EM | NF2215EM | NUP2212E |

| NU230(M) | NJ420 | NF2216EM | NUP2213E |

| NU232(M) | NJ421 | NF2217EM | NUP2214E |

| NU234(M) | NJ422 | NF2218EM | NUP2215E |

| NU236(M) | NJ423 | NF2219EM | NUP2216E |

| NU238(M) | NJ424 | NF2220EM | NUP2217E |

| NU240(M) | NJ425 | NF2230 | NUP2218E |

| NU244(M) | NJ426 | NF2232 | NUP2219E |

| NU308(M) | NJ427 | NF2234 | NUP2220E |

| NU309(M) | NJ428 | NF2306 | NUP2305E |

| NU310(M) | NJ2208E | NF2307 | NUP2306E |

| NU311(M) | NJ2209E | NF2308 | NUP2307E |

| NU312(M) | NJ2210E | NF2309 | NUP2308E |

| NU313(M) | NJ2211E | NF2310 | NUP2309E |

| NU314(M) | NJ2212E | NF2311 | NUP2310E |

| NU315(M) | NJ2213E | NF2312 | NUP2311E |

| NU316(M) | NJ2214E | NF2313 | NUP2312E |

| NU317(M) | NJ2215E | NF2314 | NUP2313E |

| NU318(M) | NJ2216E | NF2315 | NUP2314E |

| NU319(M) | NJ2217E | NF2316 | NUP2315 |

| NU320(M) | NJ2218E | NF2317 | NUP2316 |

| NU321(M) | NJ2219E | NF2318 | NUP2317 |

| NU322(M) | NJ2220E | NF2319 | NUP2318 |

| NU323(M) | NJ2222 | NF2320 | NUP2319 |

| NU324(M) | NJ2224 | NF2322 | NUP2320 |

| NU326(M) | NJ2226 | NF2324 | NUP2322 |

| NU332(M) | NF2326 | NUP2324 | |

| NU334(M) | NF2328 | NUP2326 | |

Our Company

As a comprehensive industrial enterprise that integrates R & D and sales services, with over 20 years’ experience, especially the guaranteed supplier of China Manufacturing Network, our factory covers an area of 10,000 square meters, which enables very quick delivery.

Owning the most advanced CNC automatic production line, automatic assembly line, and a varied of testing equipment, our bearings mainly cover NSK, NTN, KOYO, NACHI, THK etc., which meets all low noise, low vibration, low friction, high precision, high sealed, high turning speed and long life requests.

FAQ

SAMPLES

1.Samples quantity: 1-10 pcs are available.

2.Free samples: It depends on the model NO., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3.It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1.MOQ: 10 pcs mix different standard bearings.

2.MOQ: 5000 pcs customized your brand bearings.

OEM POLICY

1.We can printing your brand (logo,artwork)on the shield or laser engraving your brand on the shield.

2.We can custom your packaging according to your design

3.All copyright own by clients and we promised don’t disclose any info.

SUPORT

Please visit our 1Xihu (West Lake) Dis.in bearings website, we strongly encourage that you can communicate with us through email, thanks!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Double |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Bearing Steel |

| Spherical: | Aligning Bearings |

| Load Direction: | Radial Bearing |

| Customization: |

Available

| Customized Request |

|---|

Advancements in Tapered Roller Bearing Technology

Tapered roller bearing technology has undergone significant advancements over the years, driven by the demands of modern industrial applications and the pursuit of enhanced performance, efficiency, and durability. These advancements have led to innovations in design, materials, manufacturing processes, and lubrication. Here are some key insights into the advancements in tapered roller bearing technology:

- Advanced Bearing Materials:

Manufacturers are exploring new materials and alloy compositions to improve bearing strength, fatigue resistance, and high-temperature performance. Specialized coatings and surface treatments are applied to enhance corrosion resistance and reduce friction.

- Optimized Design and Geometry:

Modern design techniques, such as computer-aided modeling and simulation, allow for the optimization of bearing geometry and internal structures. This results in improved load distribution, reduced stress concentrations, and enhanced overall performance.

- Improved Cage Designs:

Cage designs have evolved to ensure better roller guidance, reduced friction, and minimized wear. Innovative cage materials and shapes enhance lubricant flow and promote efficient operation, especially at high speeds.

- Enhanced Lubrication Systems:

Advancements in lubrication technology have led to the development of specialized lubricants and lubrication systems. These solutions offer better protection against wear, reduce friction, and ensure consistent lubrication even in challenging operating conditions.

- Precision Manufacturing Techniques:

Modern manufacturing methods, such as precision grinding and superfinishing, allow for tighter tolerances and improved surface finishes. This contributes to smoother rolling contact, reduced vibration, and lower noise levels.

- Integrated Sensors and Monitoring:

Advances in sensor technology enable the integration of condition monitoring systems within tapered roller bearings. These sensors provide real-time data on factors like temperature, vibration, and lubrication, allowing for predictive maintenance and performance optimization.

- Customization and Application-Specific Solutions:

Manufacturers offer more customization options to cater to diverse industrial applications. This includes bearings optimized for specific operating conditions, load requirements, and environmental challenges.

- Digitalization and Industry 4.0:

The integration of tapered roller bearing data into digital platforms aligns with the principles of Industry 4.0. Remote monitoring, predictive analytics, and digital twins are used to enhance maintenance strategies and maximize bearing lifespan.

- Energy Efficiency Focus:

Advancements in tapered roller bearing technology align with global efforts to improve energy efficiency. Reduced friction, optimized designs, and efficient lubrication contribute to overall equipment energy savings.

- Sustainability and Eco-Friendly Solutions:

Manufacturers are exploring sustainable materials and manufacturing processes to reduce the environmental impact of bearing production. Eco-friendly lubricants and packaging solutions are also gaining attention.

Overall, advancements in tapered roller bearing technology continue to drive innovation across industries, providing solutions that meet the evolving needs of modern machinery and contribute to improved performance, reliability, and sustainability.

Are there different cage materials commonly used in cylindrical roller bearings?

Yes, there are different cage materials commonly used in cylindrical roller bearings. The cage, also known as a retainer or separator, is a critical component that holds the cylindrical rollers in position and maintains their proper spacing. The choice of cage material depends on various factors such as application requirements, operating conditions, and the desired balance between strength, durability, and cost. Let’s explore some of the commonly used cage materials in cylindrical roller bearings:

- Steel:

Steel cages are widely used in cylindrical roller bearings due to their excellent strength, durability, and wear resistance. Steel cages can withstand high operating temperatures and are suitable for applications with heavy loads and high-speed operation. The steel cages are typically made from low carbon steel, and in some cases, high-strength brass-coated steel or other alloyed steels are used for enhanced performance in demanding environments.

- Brass:

Brass cages offer good strength, high corrosion resistance, and excellent heat dissipation properties. They are commonly used in cylindrical roller bearings for applications that require resistance to harsh operating conditions, such as high temperatures or corrosive environments. Brass cages are particularly suitable for slow to moderate speed applications where their excellent thermal conductivity can help dissipate heat effectively.

- Polyamide (Nylon):

Polyamide cages, often referred to as nylon cages, are lightweight, corrosion-resistant, and have good wear properties. They offer low friction and allow for smooth rolling motion of the cylindrical rollers. Polyamide cages are commonly used in applications where reducing weight and inertia are important considerations, such as automotive and aerospace industries. They are also suitable for applications with moderate speeds and operating temperatures.

- Phenolic Resin:

Phenolic resin cages are known for their high strength, low friction, and excellent dimensional stability. These cages provide good resistance to wear, chemicals, and heat. Phenolic resin cages are commonly used in high-speed cylindrical roller bearings where low cage weight and inertia are crucial for reducing friction and maintaining stable operation at high rotational speeds.

- Other Materials:

In addition to the above-mentioned materials, other cage materials such as aluminum alloys, stainless steel, and engineered plastics may be used in specific applications. Aluminum alloy cages offer lightweight properties and good corrosion resistance, making them suitable for certain industries. Stainless steel cages provide high corrosion resistance and are used when the bearing operates in aggressive environments. Engineered plastics, such as PEEK (polyether ether ketone) or PTFE (polytetrafluoroethylene), are used for their self-lubricating properties, chemical resistance, and low friction characteristics.

The choice of cage material depends on factors such as load, speed, temperature, lubrication, and environmental conditions. Bearing manufacturers carefully select the appropriate cage material to ensure optimal performance, longevity, and reliability of the cylindrical roller bearing in a specific application.

What are the key advantages of using cylindrical roller bearings in various applications?

Cylindrical roller bearings offer several key advantages that make them a preferred choice in various applications. Let’s explore the significant benefits of using cylindrical roller bearings:

- High Radial Load Capacity:

Cylindrical roller bearings are specifically designed to handle high radial loads. Their cylindrical roller arrangement and large contact area with the raceways enable them to distribute loads evenly along the rollers’ length. This characteristic allows cylindrical roller bearings to support heavy machinery components and handle substantial radial forces, making them suitable for applications where the primary load is radial in nature.

- Moderate Thrust Load Capacity:

While their primary function is to carry radial loads, cylindrical roller bearings can also accommodate moderate axial loads. The arrangement of the cylindrical rollers and their contact angle with the raceways enables these bearings to handle limited thrust loads. However, it’s important to note that for applications with predominantly axial loads, other types of bearings, such as thrust bearings, may be more suitable.

- High-Speed Capability:

Cylindrical roller bearings can operate at high speeds, depending on their design and internal clearance. Factors such as cage material, roller design, and lubrication play a role in determining the maximum allowable speed. The ability to operate at high speeds makes cylindrical roller bearings suitable for applications that require efficient and reliable rotation, such as electric motors, gearboxes, and machine tool spindles.

- Application Versatility:

Cylindrical roller bearings find wide applications in various machinery and equipment. They are commonly used in rotating machinery, such as electric motors, gearboxes, pumps, and compressors. Cylindrical roller bearings are also utilized in industries such as automotive, aerospace, construction, and mining, where they support heavy loads and provide rotational motion in critical components. The versatility of cylindrical roller bearings makes them a preferred choice across different sectors.

- Alignment and Compensation:

Cylindrical roller bearings have the ability to accommodate slight misalignments between the inner and outer rings. This feature allows for easier installation and helps compensate for mounting errors or shaft deflections during operation. The axial displacement capability of cylindrical roller bearings can also assist in thermal expansion or contraction of the shaft and housing. This ability to handle misalignment and axial displacement contributes to the overall reliability and longevity of machinery.

- Durability and Longevity:

Cylindrical roller bearings are designed to withstand heavy loads, shocks, and vibrations encountered in various applications. They are manufactured with high-quality materials and undergo stringent quality control processes to ensure durability and reliability. Proper lubrication and maintenance further enhance their longevity and performance, making cylindrical roller bearings a dependable choice for demanding industrial environments.

In summary, cylindrical roller bearings offer significant advantages in terms of high radial load capacity, moderate thrust load capacity, high-speed capability, application versatility, alignment and compensation capabilities, and durability. These advantages make cylindrical roller bearings well-suited for a wide range of machinery applications, contributing to efficient operation, reduced downtime, and extended service life.

editor by CX 2024-04-24